Zelvo Energy Solution Pvt Ltd

Zelvo Energy Solution Pvt Ltd

Cable Tray & Accessories – Custom Solutions for Every Need

At ZESPL, we offer cable tray systems that are customizable to suit the unique requirements of your projects. Our cable trays are available in a variety of sizes and materials, ensuring you get the perfect solution for your cable management needs, whether for commercial, industrial, or residential applications.

ZESPL supply perforated and ladder type cable trays and all accessories for various industries globally.

Cable Trays are available in different sizes as per the customer specifications. As per the requirements raw materials of the cable trays will be MS, GI, and SS. We are competent to supply with different finishes like Hot dip galvanized, pre galvanized, powder coated, painted etc.

Hot Dip Galvanized (HDG) Cable Trays & Accessories

Hot Dip Galvanizing is the process of coating steel or iron with a thick layer of zinc to provide exceptional protection against rust and corrosion. It is ideal for outdoor installations or environments with high moisture, chemicals, or extreme weather conditions.

Pre-Galvanized Cable Trays & Accessories

Pre-Galvanizing involves coating the steel with zinc before fabrication. This process is typically more economical than hot dip galvanizing, offering good corrosion resistance, though with a thinner zinc coating.

Powder Coated Cable Trays & Accessories

Powder coating is a dry finishing process that involves applying a powder (usually polyester or epoxy) to metal trays and then curing them under heat to create a tough, durable finish. This finish provides both aesthetic appeal and added protection against environmental factors.

Painted Cable Trays & Accessories

Painted cable trays are coated with a layer of liquid paint, providing a protective finish that can be customized for different environments and aesthetic preferences. While not as durable as other finishes, painted trays are ideal for light-duty environments.

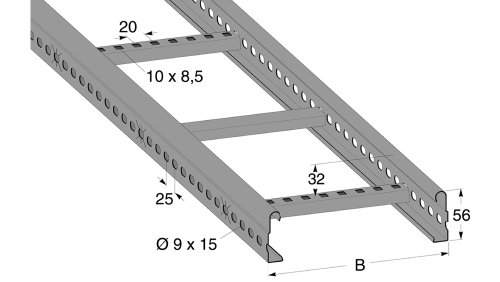

Ladder Type Cable Trays – Reliable and Flexible Cable Management

At ZESPL, we offer Ladder Type Cable Trays designed to provide exceptional support and protection for cables in a variety of industrial, commercial, and residential applications. Ladder type trays are perfect for large-scale installations, heavy-duty cable management, and high-performance environments due to their open design that promotes airflow and heat dissipation.

Our ladder trays are available in a range of thicknesses and widths to accommodate any project requirement, ensuring your cable management system is both safe and efficient.

Here’s a refined section of content specifically for Ladder Type Cable Trays, focusing on the available thickness and width options, along with other key features for your webpage

Key Specifications

Thickness OptionsLadder type cable trays are available in the following thicknesses, giving you the flexibility to choose the perfect fit for your application:

- ➢ 1.2 mm

- ➢ 1.5 mm

- ➢ 1.6 mm

- ➢ 2.0 mm

- ➢ 2.5 mm

- ➢ 3.0 mm

The thickness of the tray influences its load-bearing capacity and durability, allowing you to select the ideal strength for your specific cable load and environmental conditions.

Width Options

Choose from a wide range of widths to meet your cable management needs:

- ❖ 50 mm to 1000 mm

The width of the tray allows for flexibility in routing cables of various sizes and volumes, ensuring that cables are efficiently organized and secured.

Here’s a dedicated section for Perforated Type Cable Trays that highlights the thickness and width options for your webpage:

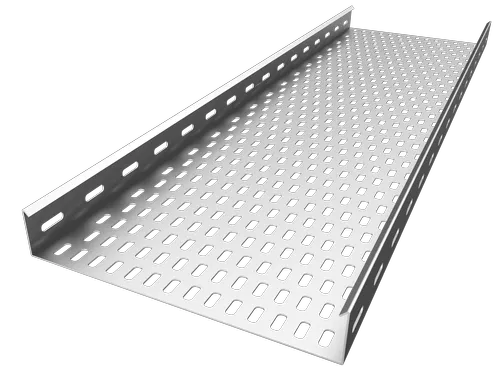

Perforated Type Cable Trays – Efficient Cable Management with Versatility

At ZESPL, we provide high-quality Perforated Type Cable Trays that are designed for efficient cable management in both light and heavy-duty applications. These trays are ideal for installations where you need secure cable routing with the added benefit of ventilation through the perforated holes, helping to prevent cable overheating and maintain system efficiency.

Our perforated cable trays are available in a variety of thicknesses and widths, giving you the flexibility to choose the best solution for your specific project needs.

Key Specifications

Thickness Options Our perforated type cable trays are available in the following thicknesses:

- ➢ 1.6 mm

- ➢ 2.0 mm

- ➢ 2.5 mm

The thickness determines the strength, durability, and load-bearing capacity of the tray, allowing you to select the optimal tray based on the required cable load and the environment in which the tray will be used.

Width Options

We offer a wide selection of widths for our perforated cable trays, ensuring the versatility to fit various cable management needs:

- ❖ 50 mm

- ❖ 100 mm

- ❖ 150 mm

- ❖ 200 mm

- ❖ 250 mm

- ❖ 300 mm

- ❖ 450 mm

- ❖ 600 mm

- ❖ 750 mm

With these width options, you can easily organize and route cables of different sizes and quantities, allowing for efficient and secure installations in any setting.

Cable tray accessories for perforated and ladder type cable trays are,

Vertical bends

Horizontal bends,

Inside bends,

Outside bends,

T-Joints and

Cross Joints

Vertical Bends

Used to change the direction of the cable tray vertically, allowing cables to move between different floors or levels.

Essential for multi-floor installations, such as industrial plants, data centers, or office buildings.

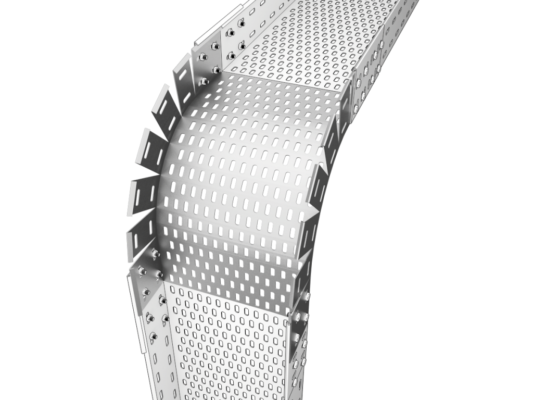

Horizontal Bends

Designed to turn the cable tray in a horizontal direction, facilitating changes in the tray’s path across large horizontal areas or around obstacles.

Ideal for installations that require lateral cable routing or to navigate around structural elements.

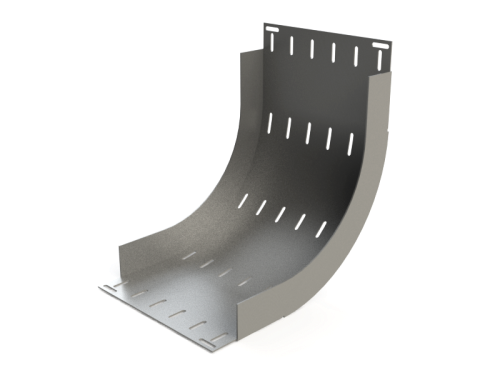

Inside Bends

These bends allow the tray to change direction inward, helping to create smooth corners or turns inside a building or structure.

Used when the cable tray needs to fit into tight spaces or redirect cables in confined areas, such as utility rooms or server rooms.

Outside Bends

Outside bends are used for changing the tray’s direction outward, useful for installations where the cable tray needs to route around corners or obstacles in the external environment.

Typically used for external cable routing, especially in outdoor applications or external infrastructure.

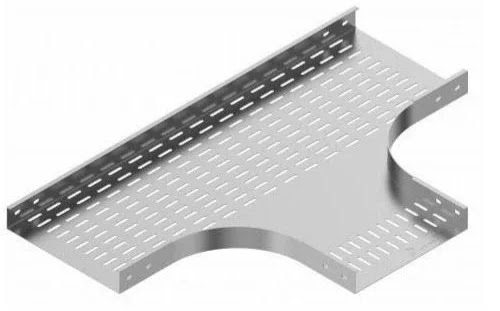

T-Joints

A T-joint connects a straight section of the tray to another at a 90-degree angle, forming a T-shape.

Perfect for branching cable trays into two directions, typically used in data centers, power plants, and electrical distribution systems.

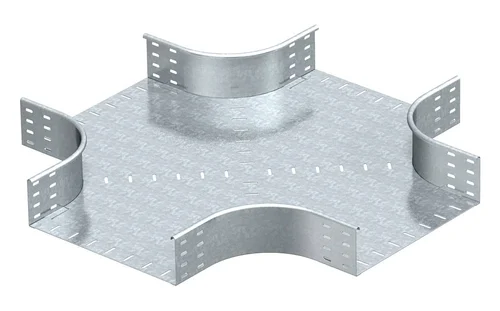

Cross Joints

A cross joint allows you to connect four sections of cable trays at 90-degree angles, forming a cross shape for multi-directional routing.

Ideal for complex cable systems, allowing for cable routes to extend in multiple directions within an industrial or commercial setup.